Review by Joe Altnether/Photos by the author

Review by Joe Altnether/Photos by the author

Our review sample of the new Atlas HO-scale RS-3 featured in the “Trains & Rolling Stock” section of the September 2017 issue of Model Railroad News was a standard DC version. This model presented the opportunity to install and test Train Control Systems (TCS) WOW Digital Command Control (DCC) decoder.

TCS offers a series of replacement kits for specific locomotives providing DCC control and sound. Included in the WOW WDK-ATL-1 kit are a Keep Alive motherboard, WOWSound decoder, speaker, speaker enclosure, and speaker wire. TCS recommends its WDK-ATL-1 for use in Atlas’ HO-scale RS-3, RSD-4/5, and RS-11 diesel models. The review of MRN’s P&LE Atlas RS-3 provided a test bed to install and evaluate TCS’ WOWSound kit.

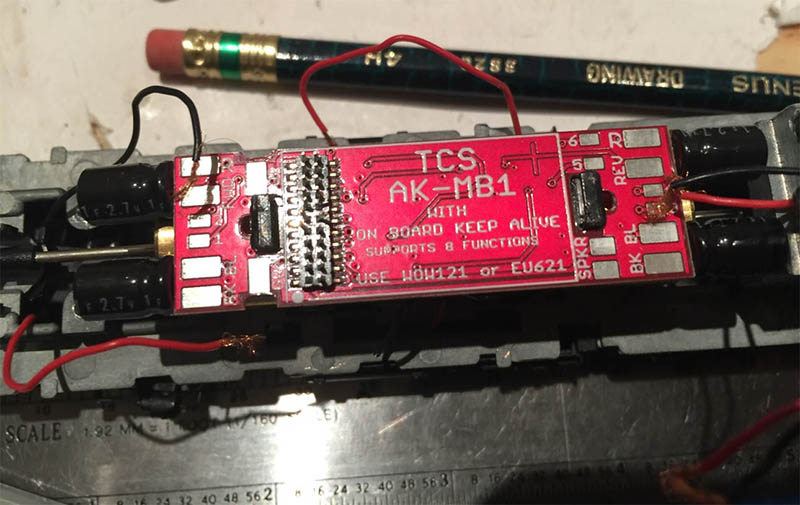

Train Control Systems product line includes a series of kits for different model locomotives from various manufacturers. TCS designs each motherboard specifically to be a direct replacement for the original board. The TCS board contains Keep Alive circuitry, a 21-pin connector for the decoder, and solder pads for all connections to the locomotive.

In addition to solder pads for the locomotive trucks and motor, the board also has pads for speaker, front and rear headlights, and functions 1 through 6. Circuits for the front and rear LED lights have resistors built into the board. Thus, the headlight LEDs can be soldered directly to the board.

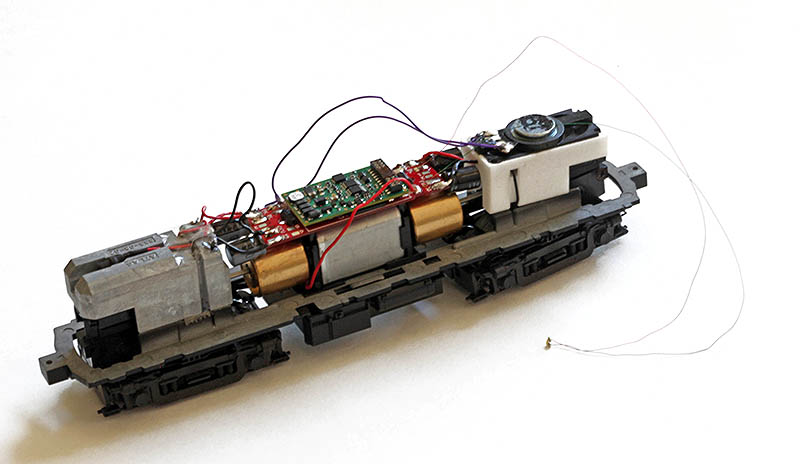

A 3D printed speaker enclosure replaces the front locomotive weight. As a result, the drawbar pull is reduced, but this occurs in any locomotive whenever metal weight is replaced by the air cavity of a speaker enclosure. Another consequence of this replacement is the elimination of mounting for the forward light. TCS recommends that a surface-mount LED be attached to the headlight casting. Not included in the kit, the LED proved to be elusive to find. Only after an exhaustive web search did I locate the needed LEDs for this project.

Three unique operating features of the kit are its Keep Alive circuitry, CD-quality sound, and Audio Assist. Keep Alive stores energy in four supercapacitors mounted on the motherboard. Supercapacitors store 10 to 100 times more energy than a regular capacitor. This energy permits the locomotive to continue running when power from the track is lost and eliminates recycling through the startup sequence of the decoder when power suddenly returns. Depending on the locomotive speed and load, the Keep Alive circuitry will power the locomotive for a minimum of up to six seconds, which is enough time to travel across dirty or unpowered track without pause or stutter. During this time of Keep Alive operation, you cannot control the locomotive, and it will continue to operate from its last received command. For the Keep Alive circuitry to be enabled, a value of two is placed in CV 182, which disables the DC mode. This is the default value in the CV. Under test with no load, I experienced 14 seconds from MRN’s Atlas RS-3 sample with a WOWSound decoder installed.

Three unique operating features of the kit are its Keep Alive circuitry, CD-quality sound, and Audio Assist. Keep Alive stores energy in four supercapacitors mounted on the motherboard. Supercapacitors store 10 to 100 times more energy than a regular capacitor. This energy permits the locomotive to continue running when power from the track is lost and eliminates recycling through the startup sequence of the decoder when power suddenly returns. Depending on the locomotive speed and load, the Keep Alive circuitry will power the locomotive for a minimum of up to six seconds, which is enough time to travel across dirty or unpowered track without pause or stutter. During this time of Keep Alive operation, you cannot control the locomotive, and it will continue to operate from its last received command. For the Keep Alive circuitry to be enabled, a value of two is placed in CV 182, which disables the DC mode. This is the default value in the CV. Under test with no load, I experienced 14 seconds from MRN’s Atlas RS-3 sample with a WOWSound decoder installed.

CD quality sound refers to the format of the stored sound data. Several pieces of TCS literature refer to “16-bit 44,100 sounds.” A 44,100HZ (44.1KHZ) sound is beyond human hearing. What is meant is that the sound information is sampled at 44,100 times per second, and each sample is digitized and stored as a 16-bit word. Sampling rate and the 16-bit word, referred to as quantization, define the quality or accuracy of the recording.

Unlike a vinyl record or a magnetic tape that have continuous information about the reproduced sound, a digital recording has only samples that are taken a regular rate. A continuously varying sound signal is converted to digital values at regularly spaced time intervals. To accurately reproduce the sound, the sample rate is very important. Humans hear sounds in the range or 20 cycle/sec (Hz) to 20,000 cycles/sec (KHz). Without going into electrical engineering theory, the Shannon-Nyquist theorem requires the sampling frequency to be at least twice the highest frequency to be sampled. Thus, to reproduce a 20 KHz signal, 40KHz is the lowest sample frequency that can be used. Unfortunately, a digital playback can create unwanted sound beyond the audio range related to the sampling frequency. Consequently, sounds above 20KHz must be filtered out. Increasing the sampling frequency by 10 percent simplifies the system design of the filter. When they invented the CD player, Philips and Sony standardized on a 44.1KHz sampling rate.

Quantization is the other important number. The size of this number describes how accurately the amplitude of the sound is represented. Except for a few values, a digital world cannot accurately represent the exact value of the sound. For example, a 2-bit word can only represent four levels of sound. This is similar to measuring a length with a ruler that has only quarter-inch marks. Any sound value between one of the four levels is rounded up or down. Thus, a value of 5/16 the maximum value would be rounded down to 1/4 the maximum value, introducing an error or distortion of the sound. With more bits, the distance between quantization levels becomes smaller, making it is possible to represent the sound more accurately. In general, more bits in the word provide better sound. A 16-bit word can represent 65 thousand different levels of sound. High-quality sound systems use 24-bit words providing 16 million different levels of sound. In model locomotives, it is the small size of the speaker that becomes the limit of the sound fidelity. How the sound decoder processes the sound samples is beyond the scope of this article and will be simply described as digital signal processing magic.

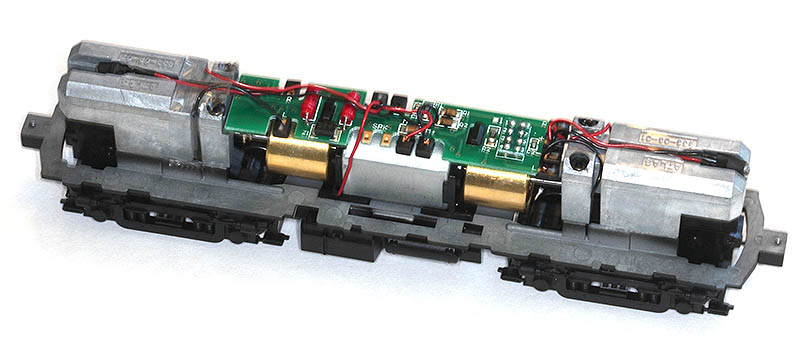

With its shell removed, the RS-3 model’s control board wires are detached, and the board is ready to be unclipped from the motor mounts.

Programming a decoder without a computer program can be challenging. TCS’ Audio Assist programming simplifies the process and overcomes many of the frustrations of programming. Sound, lighting, motor control programming, and some overhead operations are accomplished with audio feedback and without accessing a CV chart. While light, sound, and motor control are programmed with Audio Assist, programming CVs in the typical manner sets all other configurations.

After the locomotive is selected, pressing the F8 key four times enables Audio Access mode. One of four menus is selected: sound, lighting, motor control, or other options. Audio feedback identifies the selection. In the sound menu, master or individual sound levels can be adjusted; one of 33 horns and one of 49 bells can be selected. Finally, one of 13 prime movers can be selected. All the selections are listed on the website.

Lighting options include 20 effects and remapping functions. Motor control programming permits speed matching and locomotive calibration. This causes the locomotive to operate in Notch 1 lightly loaded and shifts up to Notch 8 for heavy loads.

In addition to resetting to factory setting, Other Options can configure the throttle to traditional, prototype, or manual operation. With traditional operation, the notch of the prime mover is matched to the speed, while in prototype operation, the decoder chooses the engine notch depending on the speed and load of the train. The user selects the notch number of the prime mover manually. Overall, Audio Assist is a quick and easy method to configure the decoder for a specific locomotive. The only drawback, if there is one, is scrolling through all those selections.

Getting Under the Hood

Installation begins by removing the RS-3 body shell from the frame. Finding the exact place to squeeze the body for removal requires care to prevent damaging the body mounting clips. Once the body is removed, all the wires are removed from the Atlas wiring board, and the circuit board is unclipped from the motor mounts. As shown in the instruction diagrams, the motherboard is mounted under the long hood. The long hood weight is removed to make room for the speaker enclosure. The AK-MB1 motherboard snaps onto the motor clips. Board mounting holes were a tight fit, but the AK-MB1 dimensions match Atlas exactly. All installation operations are well illustrated and described in the instructions.

Simply attached to the motor mounts, the TCS Keep Alive motherboard makes all the connections to the locomotive and replaces the original factory circuit board.

When mounted per illustrations, truck wire colors are reversed. Black truck wires aligned with the solder pads marked “Red” and red truck wires aligned to the “Black” solder pad. This color reversal is not a problem because the signal from the trucks is a non-polarized AC signal. Rather than thread the truck wires through the screw mounting holes of the speaker enclosure, I drilled two small holes in the end of the speaker enclosure for the truck wires. Shortening the speaker enclosure screws is the only modification to the locomotive.

With the truck, motor, and rear headlight wires soldered to the motherboard, only the long hood light remained to be connected. Originally, it was mounted in the weight that was removed. With no room to mount the LED above the speaker, TCS recommends mounting a surface-mount LED to the headlight lens on the body with superglue. Any experienced plastic modeler will tell you that superglue will fog clear plastic. I discussed with TCS, and the company had switched this recommendation. Hot glue and/or canopy glue should work for this project. Inserting a mini-connector in the LED leads enables separating the body and frame.

The view shows the assembly job complete. All that remains is to mount the speaker enclosure, attach the headlight, replace the RS-3 shell, and re-attach the couplers and this Alco diesel switcher is ready to go as a DCC and Sound model.

Once reassembled, it was time to test the Audio Assist. I programmed an Alco 244 prime mover, Rule 17 lighting, and a Leslie RS3 air horn. As advertised, Audio Assist simplified the set-up process.

Finally, it was time to run the locomotive. The decoder was set as a prototype throttle. When using this mode, TCS recommends calibrating the locomotive. Option 3 in Audio Assist simplifies this procedure. Operation was markedly different than the traditional throttle. Varying sounds for different loads and track conditions added interest to the operation. WOWKits offer versatility and variety in both sound and performance to replicate prototype performance.

WOWSound WDK-ATL-1

No. 1775, MSRP: $129.95

Train Control Systems

P.O. Box 341

Blooming Glen, PA 18911

215-453-9145