Review by David Otte/Photos by the author

Review by David Otte/Photos by the author

Although not as familiar to Americans as its current parent company perhaps, Trix has been producing electric model trains since the mid-1930s. Purchased by Märklin in 1999, Trix now serves as the 2-rail Direct Current (DC) arm in the HO-scale product line, as well as representing the company in the N-scale market through its popular Minitrix brand. Over the past couple of decades, Trix has allowed many modelers here in the U.S. to add European equipment to their HO layouts and, beginning in late 2001, the Germany-based company actually began venturing into producing U.S. locomotive and rolling stock prototypes as well. Its first release was a whopper of a locomotive too — Union Pacific’s (UP) 4-8-8-4 Big Boy steam locomotive, which was reviewed in the pages of Model Railroad News in March 2002. That magnificent high-quality effort set the stage for a plethora of highly detailed steam locomotive models that followed from a variety of U.S. manufacturers in the years since.

Fast forward to 2017, after a hiatus of several years without producing any new North American-prototype tooling, Märklin/Trix rolls out of the roundhouse under full steam with another famous UP articulated steam locomotive — the 4-6-6-4 Challenger. In the same spirit as its Big Boy, the die-cast metal replica offers HO-scale enthusiasts an extremely well-detailed and high tech endowed piece to add to their motive power roster.

Union Pacific Challenger No. 3985 pulls an excursion train through the American heartland. Modern-day modelers have an excuse to host big steam on their model railroads thanks to excursion programs like these. Union Pacific photo

The Challenger Story

In the years preceding World War II, Union Pacific continually found itself battling the rising costs of helpers and extra trains while needing more and more horsepower for the increasing freight traffic over the Wasatch Mountains in Utah. The road employed 2-8-8-0s and 2-10-2s in the past to move trains up the steep grades, but a more effective locomotive was needed to handle the task. Arthur H. Fetter, the General Mechanical Engineer of the UP, suggested a high-speed articulated locomotive was needed and was directed by management to come up with a design.

Under the supervision of Otto Jabelmann, Assistant Superintendent of Motive Power and Machinery, and working side by side with Alco engineers, Fetter started with the rigid wheeled 4-12-2, UP’s most powerful locomotive at the time. The six sets of drivers were split into two groups of three to give the new locomotive more flexibility. The lead truck remained the same, but a larger four-wheel trailing truck saw inclusion to handle the enlarged firebox located above the trailing truck, necessary in supplying ample steam to the two-engine arrangement. To this end, designers called for a larger boiler with a pressure rating of 255 pounds-per-square-inch with four 22×32-inch cylinders.

On August 25, 1936, Alco delivered first 4-6-6-4 steam locomotive to Union Pacific numbered 3900 and classed as “CSA-1” by the road. With an overall wheelbase, engine and tender, measuring almost 98 feet in length, the superheated locomotive featured a built-up frame, roller bearings on all engine and tender trucks, Walschaerts valve gear, 69-inch diameter drivers, a Worthington feedwater heater, mechanical stoker, twin sand domes with pneumatic sanding, an approximate weight on drivers of 400,000 pounds, and a tractive effort of more than 97,000 pounds, as well as a new semi-Vanderbilt style tender design that rode on two six-wheel trucks. Hailed a success by everyone involved, 15 additional units followed that same year. While originally assigned to the freight pool, the 4-6-6-4s were actually considered dual-purpose locomotives and assigned to fast passenger work when the need arose. By the end of 1937, an additional 25 almost identical locomotives had been delivered, designated CSA-2s, bringing the total up to 40.

The cab end of the Challenger features sliding side windows and opening vent on top. Note also the turbo generator forward of the cab, as well as the turbo water pump down below. In between is a host of wire formed railings and piping and crisp molded-in details on the die-cast metal boiler shell.

As the story goes, apparently it was William Jeffers, the Executive Vice President of the Union Pacific in 1936, who coined the name of these new locomotives as “Challengers.” It was suggested by the Superintendent of Motive Power that the 3900 be put to the test, unassisted, at the head of a train on the Ogden–Green River line through the Wasatch Range in Utah, stating that this would be “a challenge for any locomotive.” Jeffers concurred and decided then and there that the UP advertising department would refer to the new locomotives as Challengers in all future press releases.

Due to the success of the 4-6-6-4 and the emerging wartime traffic, Union Pacific ordered an additional 65 Challengers between 1942 and 1944 in three groups now classed as 4664-3, 4664-4, and 4664-5. The new locomotives, and the basis for the Märklin/Trix rendering, were slightly heavier by about 4,000 pounds, had its boiler pressure increased to 280 pounds, and displayed a somewhat modified appearance from the original design. While many of the basic dimensions stayed the same (the overall wheelbase, engine, and tender were stretched by almost nine feet, however), the most obvious visual difference was the tender — now of a larger centipede design. The new tender’s capacity increased to hold 28 tons of coal and 25,000 gallons of water versus the original’s 19,000-gallon, 22-ton capacity tenders. In particular, the larger tender eliminated many intermediate servicing stops. Other external appearance changes included moving the location of the headlight from the smokebox down to the pilot, and an extremely large twin smokestack with encompassing shroud replaced the smaller single stack found on the older Challengers.

While originally being numbered within the 3900 series (3900-3999) — every number not used, nor consecutively either — time would see most of the early units renumbered. Some were renumbered to the 3800 series, and a handful of the fleet entered the 3700 series as a number of the engines were converted from coal to oil burners (and some even back to coal again), assigned to passenger service, or to make way for additional locomotives on the roster. Besides receiving modifications for differing fuel types, many of the units designated for passenger service were outfitted with smoke deflectors or, as preferred by UP company men, “wind wings” to improve the engineer’s visibility and to keep the exhaust out of the cab. A handful of Challengers pulling passenger duty would also have their basic black attire replaced by the eye-catching two-tone gray paint with silver or yellow pin striping too, which made these 4-6-6-4s even more memorable to railfans.

The oil-style tender is just as detailed as the locomotive with its centipede wheel arrangement; metal access ladders; piping above the trucks; multiple water hatches up top; toolbox; and oil fill hatch, valves, and vents; working rear marker lights; wire hand rail along the perimeter of the top deck; and fine, molded-in rivet detail throughout the body shell. Note the standard NEM 362 pocket with hook and loop coupler accompanying the Trix model has been replaced with a Kadee No. 18 knuckle coupler.

The oil-style tender is just as detailed as the locomotive with its centipede wheel arrangement; metal access ladders; piping above the trucks; multiple water hatches up top; toolbox; and oil fill hatch, valves, and vents; working rear marker lights; wire hand rail along the perimeter of the top deck; and fine, molded-in rivet detail throughout the body shell. Note the standard NEM 362 pocket with hook and loop coupler accompanying the Trix model has been replaced with a Kadee No. 18 knuckle coupler.

Eventually, eight other railroads also purchased and operated some 147 additional 4-6-6-4 types, including Clinchfield; Delaware & Hudson; Denver & Rio Grande Western; Great Northern; Northern Pacific; Spokane, Portland & Seattle; Western Maryland; and Western Pacific. While Alco built the majority of the Challengers, Baldwin Locomotive Works constructed a total of 27 locomotives for Western Maryland and Rio Grande. By the early 1960s, UP’s entire Challenger class had been retired and most scrapped, the exceptions being No. 3977 on static display in North Platte, Nebraska, and the operational No. 3985. UP 3985 has seen use on various Union Pacific customer and employee appreciation trips since the early 1980s through 2010 and is currently awaiting a major rebuild.

The Märklin/Trix Challenger

If you are already the owner of a Trix HO-scale Big Boy model, then you know what to expect regarding this new Challenger. For those new to Trix, boy, are you in for a treat! A signature of these big, articulated steam locomotive releases, Trix’s HO-scale 4-6-6-4 arrives doubled boxed and encased in a foam-lined wooden presentation case. The case, exhibiting a rich mahogany finish and polished brass latches and hinges, opens to reveal a steam locomotive measuring 16¾-inches in length over pilot and tender coupler. She’s a heavy beast too with the twin engine and centipede tender duo weighing in at around three pounds and thus requiring the model to be fastened to a wood base. The immediate challenge is how to remove the screws beneath the base and release the 4-6-6-4 model safely. To that end, the upper foam insert acts as a locomotive cradle and, placing it in the bottom half of the box, I found turning the model upside down into the cradle and then removing the screws from the base worked well. You can then lift the semi-permanently connected engine and tender out of the box with two hands, one firmly grasping the boiler and the other the tender shell, and gentling laying it on its side, before rotating it into an upright position.

The 1:87 Challenger impresses from the get-go with details galore. The aforementioned die-cast metal shells display crisp molded-in features, such as the access hatches and bands on the boiler jacket or the abundance of tiny rivet heads populating the tender sides. However, most of the nuances of the UP 4-6-6-4 have been captured with separately applied parts, many of which are also made of metal and supplemented with injection-molded plastic pieces and wire-formed hand rail and grab irons throughout.

The new Trix 4-6-6-4 represents Union Pacific’s final group of Challengers built between 1942 and 1944. For its initial release, Trix’s HO model features an oil tender, and the locomotive is equipped with “wind wings” that aided the prototype in deflecting the exhaust smoke up and away from the cab.

There’s a lot to take in, so I’ll leave the accompanying photos to present the bulk of the details, but there are a couple of highlights worth mentioning here. While the cab reflects the enclosed design of the later prototypes, Trix has outfitted its version with positionable rooftop vent and sliding side cab windows so that one can view the detailed backhead with its red-painted valve wheels and white-faced gauges, along with the hand-painted crew figures seated before them. Then there is the running gear with blackened metal rods and valve gear, die-cast cylinders, see-through Boxpox drivers, and brake shoes and sanding lines. Add on the plethora of individual piping on both engine and tender and, well, you have one very fine-looking Challenger!

Comparing the rendering to dimensioned line drawings and photos of the prototype yields the fact that Trix did its homework when recreating the 4-6-6-4 for HO. Nothing stood out to my eyes as misrepresented, nor were the general proportions of the engine and tender found to be in error. However, the manufacturer has taken the usual liberties with the running gear and the drawbar between the duo to make the model operational in the HO-scale world. This means that the drivers are a bit undersized at 64 scale inches in diameter, while the appropriate spacing between each has been maintained. The lead truck has been moved about 5 scale inches forward and the drawbar extended in length causing the overall wheelbase to be about two scale feet longer than that of the prototype. Most notable, though, is the pivoting rear engine, which on the real deal was fixed in place. The benefit of these adjustments is that modelers with small layouts can still enjoy this articulated steam locomotive on radius curves as tight as 360 millimeters (14.2 inches) — the European standard. This allows for operation on 18- to 22-inch radius curves with the only consideration being regard for right-of-way clearances due to the overhang of this large model as it navigates tight curves.

There are plenty of separately applied details to enjoy on this Challenger: illuminated number boards, brass bell, working maker lights, wire handrail and grabs, see-through pilot, LED-equipped headlight, coupler cut lever, wind wings, air pumps behind the front shield, and maintenance platform with raised tread plate.

For its initial release (including a 3-rail alternating current [AC] version sold under Märklin’s name), the company has chosen to replicate only a single unit, UP’s No. 3706, as equipped with an oil tender and wind wings. This particular prototype began life as coal-burning UP No. 3943, delivered in the last batch of 20 Challengers (3930–3949) in August 1944. While it’s generally believed that only passenger units received wind wings, two Challengers assigned to freight duty were experimented with regarding these accouterments as well, No. 3943 being one of them and receiving its wings in 1948. In 1952, the locomotive was converted over to burn oil and at that time renumbered to No. 3706, the road number it would keep until being officially retired in March 1961 — still displaying its wind wings.

The paint and lettering application on MRN’s sample was certainly up to industry standards. While classed as a freight locomotive, the HO-scale No. 3706 wears a silky smooth satin black finish on most of its surfaces that still allows all the great molded-in details to remain sharp and visible. The only highlights offsetting the basic attire are the silver-painted firebox and smokebox, as well as the brighter metal finish of the rods and valve gear. The aluminum-colored Gothic-style lettering does its job too on the cab and tender sides, tender rear, and, of course, the miniature UP shield herald on the smokebox front. Everything looked to follow UP practice in this department except for the locomotive classification listed on the cab side, which referred to No. 3706 as a “4664-4” rather than the correct “4664-5” designation, according to my research information. A minor grievance for sure, considering the necessity of a strong magnifying glass just to read it. Furthermore, UP commenced painting the engine truck axle ends aluminum as well beginning in about 1952 and photos of No. 3706 dated for 1956 and 1959 both show this to be the case. This latter detail is absent from the Trix offering, but an easy fix for modelers who wish to portray their Challenger for the later 1950s.

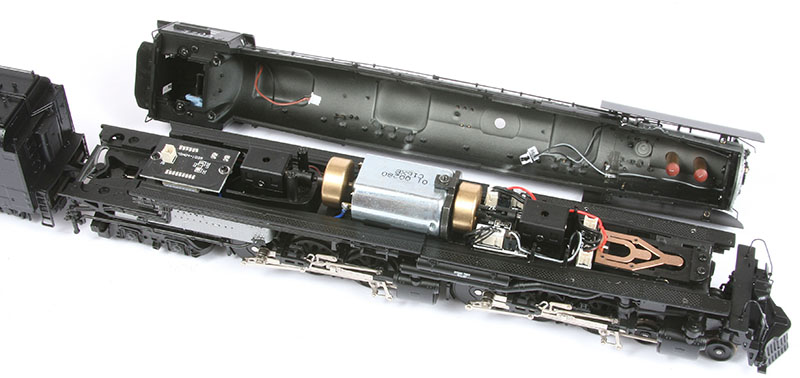

The boiler shell can be disassembled by removing a total of seven screws: four behind the wind wings, one hidden beneath the top of the steam dome, and two from the under side of the cab, revealing the powerful drive. Note the smoke generators have been installed (protruding through the bottom of the shell) and make contact with the copper plates at the front of the chassis. Although difficult to see at this angle, a sprung plastic drawbar connects the locomotive and tender with the wiring coming from the decoder to the various lighting features of the locomotive and drive wheel electrical pickups traveling through the underside of the drawbar.

Besides replicating their appearance, the factory-installed Digital Command Control (DCC) and sound-equipped Trix models are also designed to represent the impressive performance and audio effects of the Challengers. Outfitted with six-wheel drive, as powered by a single flywheel-equipped can motor mounted horizontally between the two engines’ gear towers, and with the third pair of drivers of each engine equipped with traction tires, the 1:87 locomotive is a real stump puller. I measured a drawbar pull of more than 13 ounces, equating to about 150 pieces of rolling stock, on level track. That’s incredible! Speed control is nothing to sneeze at either with a range from just more than one scale mile per hour to about 70 scale miles power, which is precisely what these behemoths were capable of out on the main line. And this was all accomplished on a test track with minimum 22-inch radius curves and No. 4 turnouts. Yes, the wheel flanges on the Trix version do look a bit large and don’t meet RP25 standards, but this sample operated over Code 83 rail just fine.

Not surprisingly, the Trix Challenger comes equipped with a standard European NEM 362-type coupler socket on the tender and typical loop-and-hook coupler. To make use of this locomotive on a typical U.S. layout, the modeler will need to purchase separately a Kadee No. 18 conversion coupler, which simply plugs into the body-mounted coupler box on the model. Regarding the pilot coupler, the prototype actually had a swing-out knuckle, but the HO-scale model isn’t quite that sophisticated. Instead, a small section of the pilot can be removed and the dummy knuckle coupler included with the model can be inserted.

Check out this view of the front engine with its see-through boxpok drivers, metal rods and valve gear, and brake show and sanding nozzle details. Note how the steam pipes at the front end of the engine are jointed and pivot with the assembly just as on the prototype. Even the air reservoir tanks stand out with tiny lettering spelling out their last hydro testing date — now that’s attention to detail!

The factory-installed decoder on board the Trix Challenger is designed for direct current (DC) analog, Märklin’s Digital, or DCC operation with a maximum operating voltage of 15 volts DC or 22 volts AC. Of interest to us here is the model’s DCC performance. Shortly after my first test run, I discovered an issue with function key assignments — they don’t follow standard DCC practice in how they are mapped out. For example, F2, almost always assigned to a playable whistle or horn, is setup to control general operating sounds on the Challenger. The problem is, on many DCC throttles, such as those produced by Digitrax, F2 is programmed as a momentary switch with the assigned audio byte only being played for the duration the button is being pressed. For my Digitrax DT402 throttle then, that means I can only hear cylinder chuff and other incidental sounds, as long as my finger is depressing the F2 key.

Normally, the DCC aficionado would simply remap the function keys, as I believe can be done with this decoder, but I could neither find any documentation on Märklin’s main website regarding the decoder parameters nor could the JMRI Decoder Pro software integrated into my programming track, which is the easiest method of adjusting the decoder of most DCC-equipped locomotives, correctly identify the decoder. Luckily, Digitrax has a method for reprogramming the F2 key on both the DT400 and DT402 throttles to make them function as on/off buttons. While this modification allowed me to experience the operating sounds of the 4-6-6-4, it also required me to modify my operating practices regarding other locomotives being operated on the same layout with the Challenger.

Other than this issue, the Trix Challenger was a sweet-sounding ride. There are 28 different functions to engage from the usual whistle and bell to the air pump with some out of the ordinary audio bytes to enjoy too, such as the sound of the cab windows being slid closed or the ventilation flap being opened; fuel and water being added to the tender; oil being added to the combustion chamber; and an exchange between crewmates Fred and Ernie in the cab wondering if they will make Cheyenne on schedule. Overall sound effects are quite robust and emanate from speakers in the floor of the tender. While most manufacturers of articulated locomotives prescribe to the chuff sounds of the two engines going in and out of synch with one another, as occasionally caused by wheel slippage on the prototypes, Trix keeps its engines in synch with a strong, combined chuff being heard throughout operation.

Along with the sound functions are several lighting controls to manipulate as well. First, the headlight, number boards, and front-and-rear marker lights are all LED equipped and bright enough to be seen in a well-lit room. A cool feature is F8, which switches on the cab lighting, so all those previously mentioned cab details can be more easily seen. Next, F10 operates the number boards and front white marker lights independently from the headlights; F14 controls the red marker lights on the rear of the tender. However, the red emergency tender light, which is also modeled, is non-functioning. For the marker lights to be functional, their fixtures do appear a bit larger than scale, but I like the effects achieved and can live with the disparity.

As an option, the HO-scale 4-6-6-4 comes ready to be equipped with smoke generators. The small cylindrical devices simply push into the exhaust stack openings and make electrical contact with the base of the smokebox. Smoke fluid, such as that produced by Seuthe, is then conservatively added to produce fluffy clouds of white smoke. The generators can be controlled using the F1 function on the DCC throttle.

Finally, Trix offers one aftermarket upgrade for its Challenger too: smoke generators. Accessory No. 7226 provides a unit that simply pushes into the existing exhaust stack openings (two smoke generators are required for this prototype) and can be turned on/off remotely under DCC via the F1 key. This is obviously not a fan-driven smoke mechanism and therefore not actually synched with the driver revolution nor chuff sounds, but the accessory simply provides a constant stream of fluffy white exhaust from the stack. Smoke fluid is not included, but I would recommend the purchase of Seuthe brand fluid for best performance.

A Real Collector’s Piece

Barring the DCC function key mapping issue, I feel Trix has done a fabulous job in the presentation and recreation of this UP prototype. The Challenger, like the company’s previous Big Boy release, will surely rate a real collector’s piece in the years to come. Operators will no doubt find its smooth performance, abundance of sound and lighting effects, and optional smoke generators to rival anything already on their locomotive rosters. I would also imagine that we will see several variants of the 4-6-6-4 prototype available in model form too. Paired with a coal tender, units without wind wings, and the two-tone gray passenger paint schemes, just to mention a few possibilities, will make for some interesting Challenger offerings by Trix down the road.

Trix HO-scale

Challenger 3900-Class steam locomotive

Union Pacific No. 3706

#T22939, MSRP: $799.99

Trix from Märklin, Inc.

P.O. Box 510559

New Berlin, WI 53151-0559

800-825-0888